Table of Contents

- The power and speed of an aircraft engine is determined by its RPM, where higher RPM usually translates into more power.

- Turbofans can run anywhere from 2500 to 4500 RPM, although normal aircraft engines typically run at an average of 2500 RPM.

- The gear turbofan technology of the Pratt & Whitney PW1000G engine results in higher fuel economy but more complicated maintenance because the fan and compressor have separate RPMs.

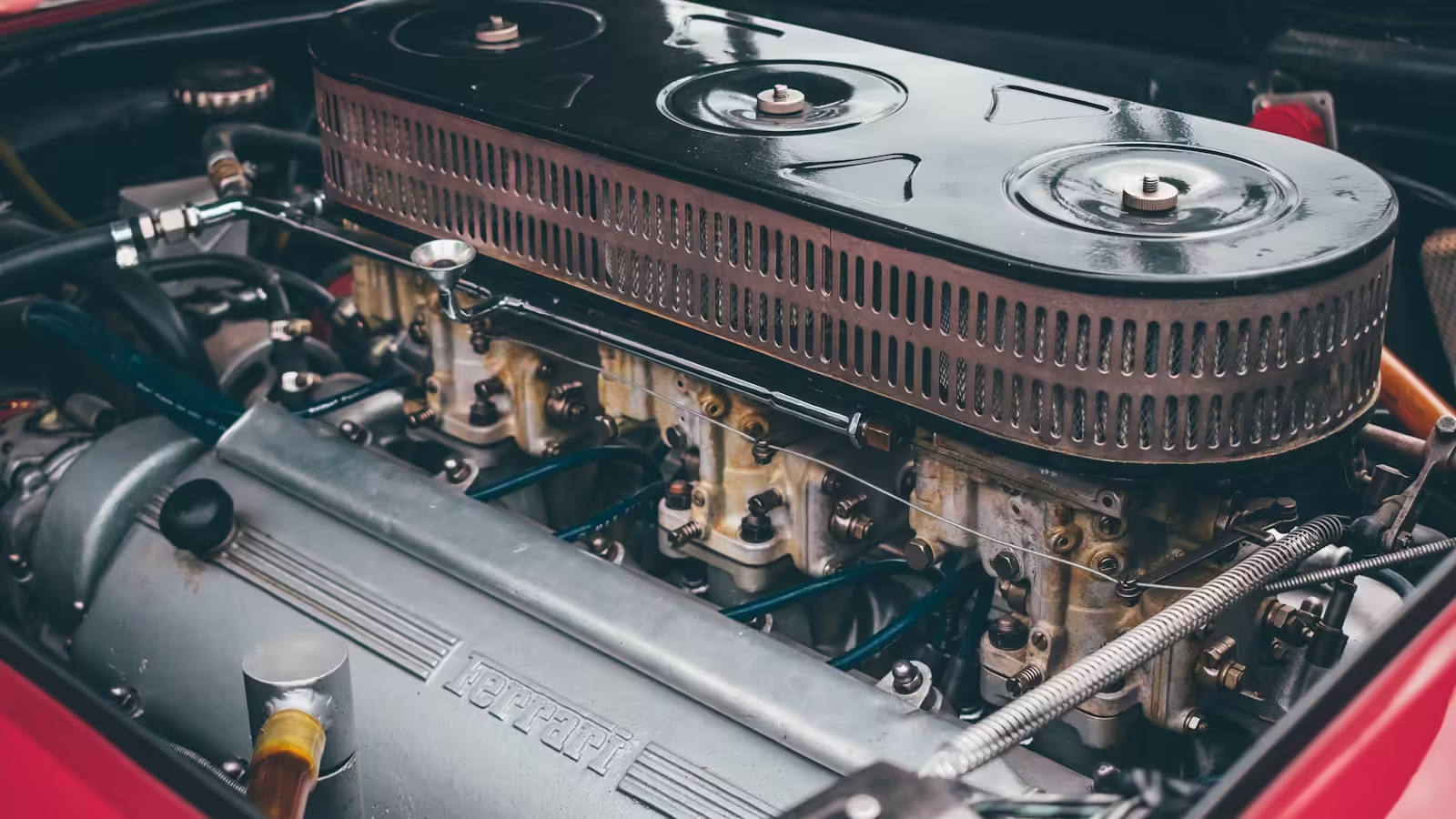

Engines are undoubtedly the most important parts of an aircraft. Propulsion is produced by the acceleration of air in almost all engine types, and depending on the particular machine, this air can be combined with jet fuel and ignited in various ways. All conventional aircraft engines, except ramjets, require rotational motion

The propellers are rotated by turboprops and piston-driven engines to provide thrust; The rotational rate of an engine is measured in revolutions per minute (RPM). Turboprop engines are generally more powerful and have a faster propeller spin speed when their RPM in the powerplant is higher.

Most commercial jet engines operate in a similar manner, with air generated by fan blades that pass through the turbofan’s compressor, and some rotate completely around it. Supersonic aircraft are usually powered by turbojet engines, which do not have air bypassing the compressor but still have a fan at the front of the engine.

The RPM of the engine is determined by the rotational speed of the fan, which is between 2500 and 4500 for most commercial aircraft. In this article, we will take a closer look at the role RPM plays in engine technology and aircraft operations.

Revolutions per minute, or RPM, is an important aviation metric that expresses how many complete revolutions an aircraft engine’s crankshaft can make in one minute. Understand the performance of the engine and the understanding of this parameter is necessary for the operating condition. RPM is a useful tool for pilots and maintenance personnel to assess aircraft engine health, efficiency and power output.

Increased engine power and thrust, which are required for takeoff, climbing and maneuvering, are often associated with higher rpm. Lower RPMs, on the other hand, are linked to fuel efficiency and cruising. For safe and effective flight operations, proper RPM management is essential to operate the engine within certain limits and avoid any mechanical failure.

Different speeds for different planes

RPMs of small general aviation aircraft such as the Cessna Skyhawk and large commercial aircraft such as the Airbus A350 seem to have dramatic differences. However, this is not always the case.

According to a test published in Plane and Pilot magazine, the average RPM of a general aviation engine often hovers around 2500, which is at the very low end of the normal range for turbofans. When comparing the aforementioned Skyhawk and A350, the study becomes even more intriguing.

According to Backcountry Pilot, the Continental O-300 piston engine that powers the Skyhawk typically runs at 2,700 rpm. Plane Nerd states that the Rolls-Royce Trent XWB’s engine, a contemporary and dynamic turbofan that powers the Airbus A350, is usually an RPM of roughly 2700 as well.

RPM New engines on the market

Conventional wisdom regarding engine RPM has been challenged by a new idea that has recently hit the market. With the addition of a new gearbox to the fan blades and low-pressure compressor, the Pratt & Whitney PW1000G engine family specifically utilizes Geared Turbofan (GTF) technology.

For the A320neo series of planes, the aerospace manufacturer made progress with its latest engine.

The new gearbox enabled two different RPM values for the engine, enabling separate shafts to rotate the compressor and fan. According to Aviation Week, the rpm of a compressor can reach 10,000, while the typical rpm of a fan is around 3,200.

Fuel economy can be increased significantly by using a gearbox that resolves the ratio of compressor to fan RPM 3:1. But such a complex engine would require more maintenance, as they have with the PW1000G can be difficult and time-consuming if a problem occurs.

READ | The history of tri-jets and rear-engined aircraft and how they got away

READ | 5 unknown facts about aircraft engines

1 thought on “RPM: What does critical RPM of an aircraft engine mean?”