Table of Contents

The use of Aircraft engine technology in other industries

The same jet engine technology used in modern aircraft is also used in ships and power generation. There are several aero types of industrial gas turbines (IGTs) that are used as jet engines in aircraft. For example, there is an IGT version of the General Electric CF6-80C2, which powers the Lockheed Martin C-5M Galaxy and the Boeing 747, known as the LM6000.

The principles of operation and working of both engines are comparable and the part numbers for many modules are also the same. The cycle time of aero derivatives is significantly shorter than that of IGT. IGTs can operate for thousands of hours on a single cycle, while a conventional widebody engine can run for only seven to twelve hours on average.

Jet engines are extremely expensive!

Because of their engineering, testing, and use of effective thermal-resistant materials, jet engines are expensive. A single jet engine component can set you back $2 million, or six Ferraris. A complete jet engine can cost anywhere from $5 million to $50 million, depending on its size and capacity.

The cost of a jet engine is determined by rigorous testing requirements and the use of specialist materials. The greatest level of precision, flexibility and strength must be used in part production. Before being retired, modern jet engines are designed to withstand thousands of flight cycles.

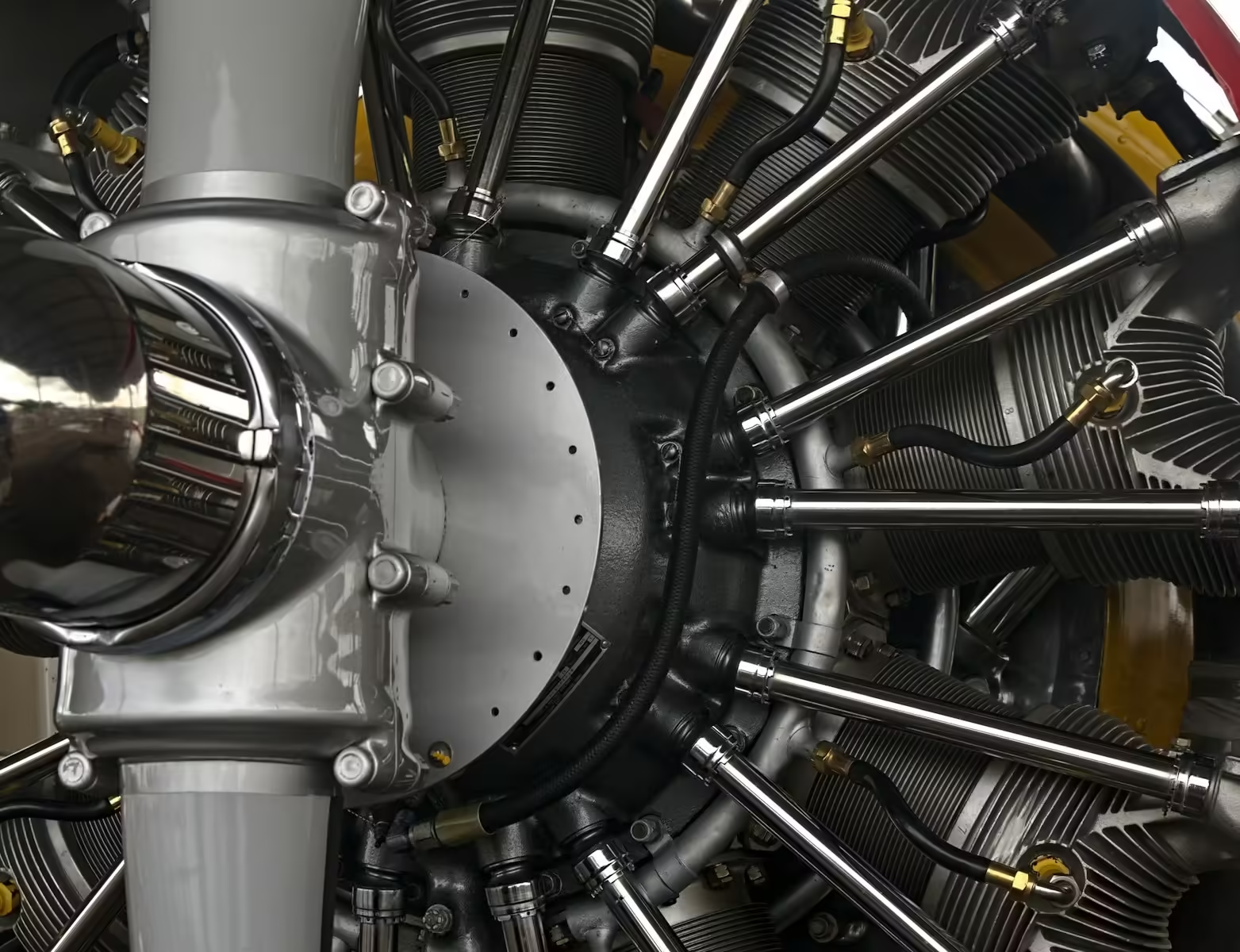

Jet engines comprise thousands of individual parts

A jet engine can have up to 45,000 different components. A modern jet engine has 25,000 to 45,000 parts. Typically, engine components are built as modular parts with separate assemblies of components.

The average GE CF6-80C2 engine used in the Boeing 747 has more than 40,000 units. There are about 2,000 distinct elements among them (classified as numeric or alphanumeric part numbers). Most of the smaller components are placed in bulk unlike larger parts.

A small portion of air runs the turbines

For power generation, the incoming air is combined with only 10-20% of the fuel. The flow of air entering the engine core (primary flow) divided by the mass flow of air bypassing the core (secondary flow) is known as the bypass ratio, and modern turbofan engines have higher bypass ratios.

A small amount of compressed air is mixed with gasoline and ignited for expansion. Most of the air passes through the bypass flow, which increases the overall thrust of the engine.

The outside temperature can significantly affect engine performance

The maximum temperature that almost all commercial jet engines can reach while operating is determined by the EGT or Exhaust Gas Temperature. This is the temperature that the turbine’s exhaust is emitting. Engine efficiency is measured by calculating the EGT margin, which is the difference between the expended takeoff ET and the redline (maximum) EGT.

For contemporary engines, an increase in outside temperature of 1 degree Celsius often results in an increase in engine temperature of about 8 degree Celsius. As the EGT margin falls, the specific fuel consumption (SFC) of the engine increases. Check out our guides section here.

Bonus: Air for the “customer” comes from the engine

Compressed air from the engine powers most contemporary jet engines, which is used for air conditioning, cabin pressurization, and other critical systems such as wing and engine anti-ice. Air is supplied to the aircraft through the bleed tap on the jet engine.

READ | RPM: What does critical RPM of an aircraft engine mean?

READ | The Pratt and Whitney engine that completely revolutionized air travel

2 thoughts on “5 unknown facts about aircraft engines”